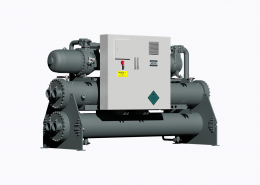

Water cooled chiller although both air cooled chillers and water cooled chillers function to remove unwanted heat from manufacturing processes they differ in various ways.

Water cooled chiller vs air cooled chiller cop.

The electrical power demand of the chiller to produce this is 460kw.

Packaged air cooled chillers are typically available in sizes ranging from 7 5 to 500 tons 25 to 1 580 kw.

F air cooled reciprocating water chillers that have five years old installation operating at full load covering nominal cooling capacities from 17 kw to 525 kw.

Water cooled chiller systems have a cooling tower thus they feature higher efficiency than air cooled chillers.

Water cooled chillers tend to have lower life cycle costs in warmer climatic regions in buildings where chillers are operated for long hours and where chiller capacity is typically larger than 1 5mw.

Water cooled chiller cost comparison.

However water cooled chillers allow the refrigeration system to operate at lower head pressure making them more efficient and less costly to operate than air cooled chillers.

Factors such as water costs efficiency ratings and electricity can dramatically change the lifetime price of a chiller.

In other words water cooled chillers can deliver higher cooling capacity with fewer units and a smaller footprint.

This means that for every 1kw of electricity you put into the machine you will produce 5 4kw of cooling.

Water efficiency is a key operational consideration where water cooled chillers are installed.

If we only look at compressor costs this may be true.

This can usually go both ways as many air conditioners can cool down as well as heat.

Water cooled chillers are more efficient because they condense depending on the ambient temperature bulb temperature which is lower than the ambient dry bulb temperature the lower a chiller condenses the more efficient it is.

Typically air cooled chillers are placed outside a building while you would keep a water cooled chiller inside.

Packaged water cooled chillers are typically available from 10 to 4 000 tons 35 to 14 000 kw.

Conventional thinking has been that water cooled chillers are more efficient than air cooled chillers.

Deciding which chiller type best suits your industrial process depends on several factors which include.

One uses the air and one uses water.

However using state of the art technology with centrifugal compressors and variable speed control air cooled chillers are often the better.

Figure 2 show that air cooled cooling systems that ranged from 17 kw to 525 kw when operated at tropical outdoor temperatures and with presence of sandy storms will have.

2 500kw 460kw 5 4 so the cop is 5 4.

The primary purpose of an air conditioner system is to manage the temperature of a room.