We service a wide range of clients throughout the united kingdom and offer a simple efficient and cost effective solution for all your sheet metal requirements including precision metal fabrication laser cutting water jet cutting and one of the few uk manufacturers to offer a full turnkey service.

Water jet cutting aluminium cost.

Approximately 50 million tons of aluminum are processed worldwide each year.

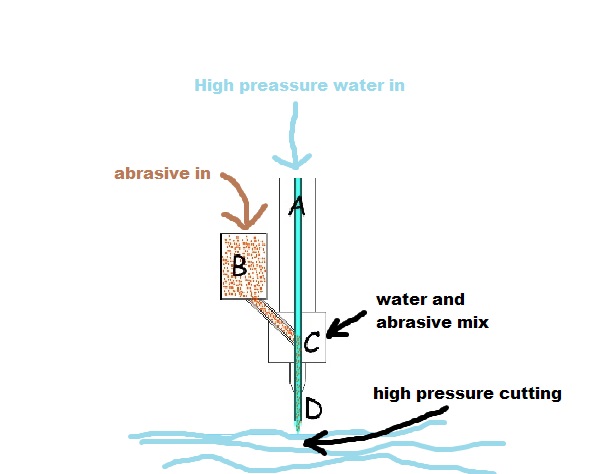

The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite while the terms pure waterjet and.

Without considering any other factors waterjet cutting is more than 5x the cost of laser cutter cost per hour.

That cost is going to total up between 1 200 and 2 500 per year.

Emsea ltd is based in tewkesbury gloucestershire.

All of our waterjet machines are equipped with multiple cutting heads that.

I m using a national average of 3 51 per 1000 gallons and i m including both maximum cutting water flow and cooling water for the hydraulics.

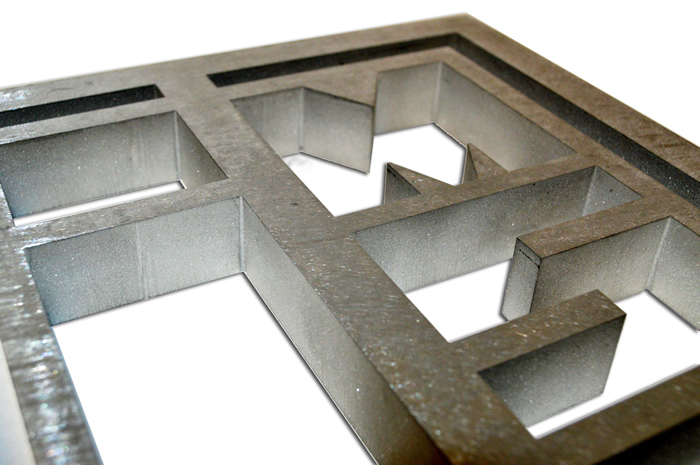

For example the engineer merely gives a gear drawing to the cutting shop via a diskette or e mail and gets the finished gear back.

20 hr 16 67 hr 333 40 for 15 000 of cutting.

The steep price is due to the expensive ultra high pressure pumps required to cut metal with water.

The smallest slice of the pie is the cost of water.

Cost to run a waterjet the short answer.

This single cutting process saves material costs and machining costs.

All calculations are based on a single abrasive waterjet cutting head.

A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high pressure jet of water or a mixture of water and an abrasive substance.

New laser machines start around 350 000 and can easily exceed 1 000 000.

At minnesota waterjet we process aluminum products for a wide variety of industries and applications.

Water only applications no abrasive are about half the cost.

180 south ave po box 517.

While there are several factors that can affect the hourly cost of running a waterjet see the long answer the following will give you a good baseline for what to expect.

Wardjet is an ohio based designer and vertically integrated manufacturer of tailored waterjet cutting solutions that are used to cut materials ranging from tinfoil to titanium.

The tiny jet stream permits the first cut to also be the final finished surface.

Waterjet cutting is a highly effective method of processing aluminum and we are equipped to handle just about any shape or size of alloy.

Finally cnc laser cutting tables are often the most expensive option.

If purchased used these machines will often cost upwards of 250 000.

We aim to produce top quality products.

Abrasive waterjet cutting can pierce or drill holes as small as 030 in diameter 0 004 for water jet without abrasive.